Amine Absorber Column Design

Chemical engineering design - GAVIN TOWLER RAY SINNOTTpdf. During operation and design of amine contactors it has been advised for some time to maintain a minimum temperature approach of 5C 10F.

Subarus EJ20K was a turbocharged 20-litre horizontally-opposed or boxer four-cylinder petrol engine.

. Design attributes power and torque outputs technology and models with this engine. A packed column was used to study the absorption of NOx in an alk. Moreover through the optimization of the temperature and concentration distribution in the absorber the mass transfer of H 2 S from column section 2 to g can be strengthened so that the concentration of H 2 S in the gas phase which is sent to the column section 1 is lower than that of the conventional process.

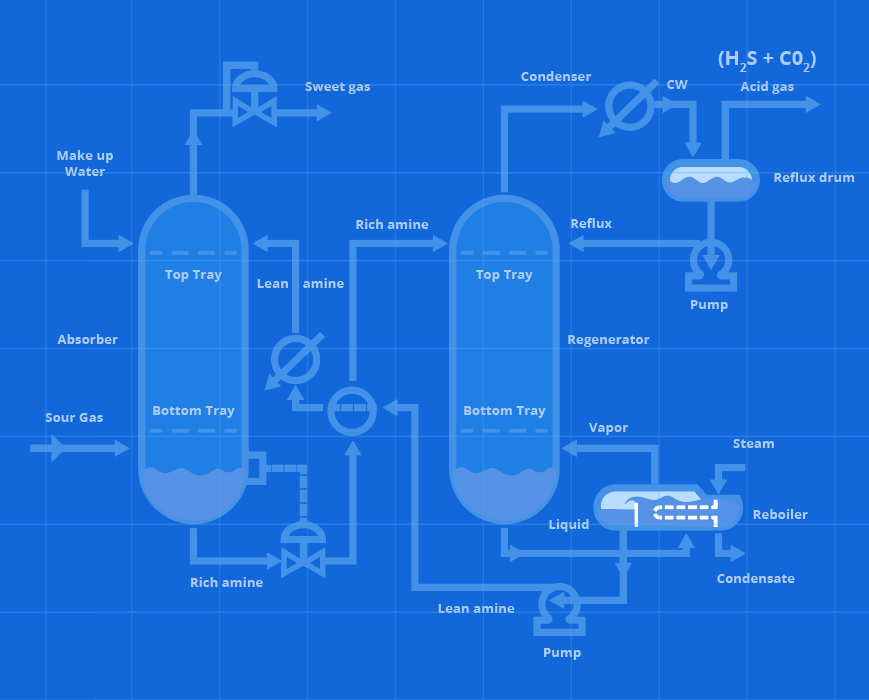

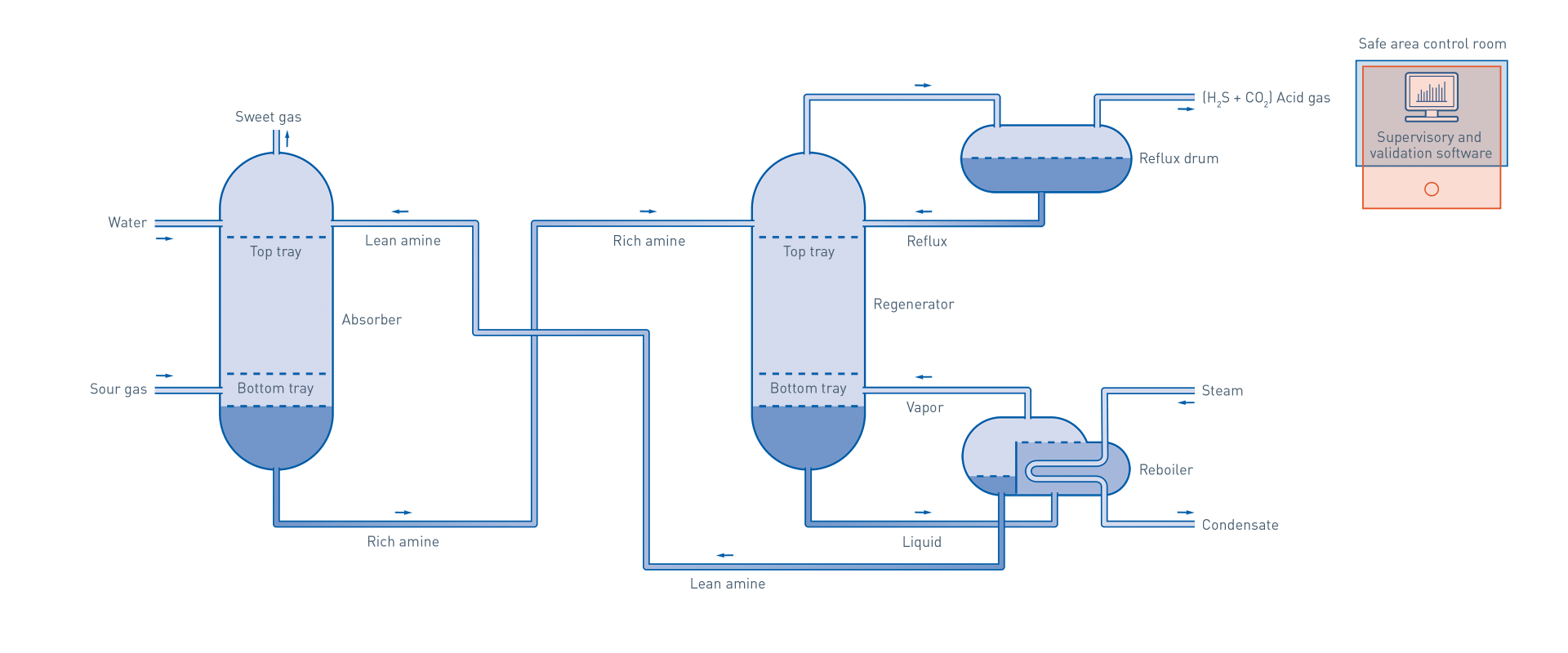

Sweet gas leaves the top of the absorber whereas the amine out of the bottom now rich with acidic components is sent to a. This Table should be read to specify the technology for a particular Coating Process only when the Resultant Coating in column 3 is in a paragraph directly across from the relevant Substrate under column 2. 2019 Taiwan Expo in India_Booth 092.

The potassium carbonate absorbs the CO 2 and travels to the desorption column to recycle the absorbent and release the CO 2 and an almost pure stream 99 of CO 2 is vented. NO was oxidized to NO2 andor to NO2- and. The stripping column operates at 28 psia with a feed and bottom temperature of 250F and a reflux temperature of 140180F.

AMPA MYANMAR 2018- Booth A113. Addition of acid or caustic for improved performance. Under the same sweetening effect both the amount of lean.

Design rates are 7 gpm of circulating absorbent and 10 lb steam per gallon of solution. And a lumped reaction model was used to est. IMAGES Subaru EJ20K Engine.

The temperature approach is defined as the temperature differential between the incoming acid gas and the lean amine feed. In Australia the EJ20K engine. This paper reviews options for sour water stripper configuration and presents a method to optimize stripper operation by finding the most efficient operating parameters.

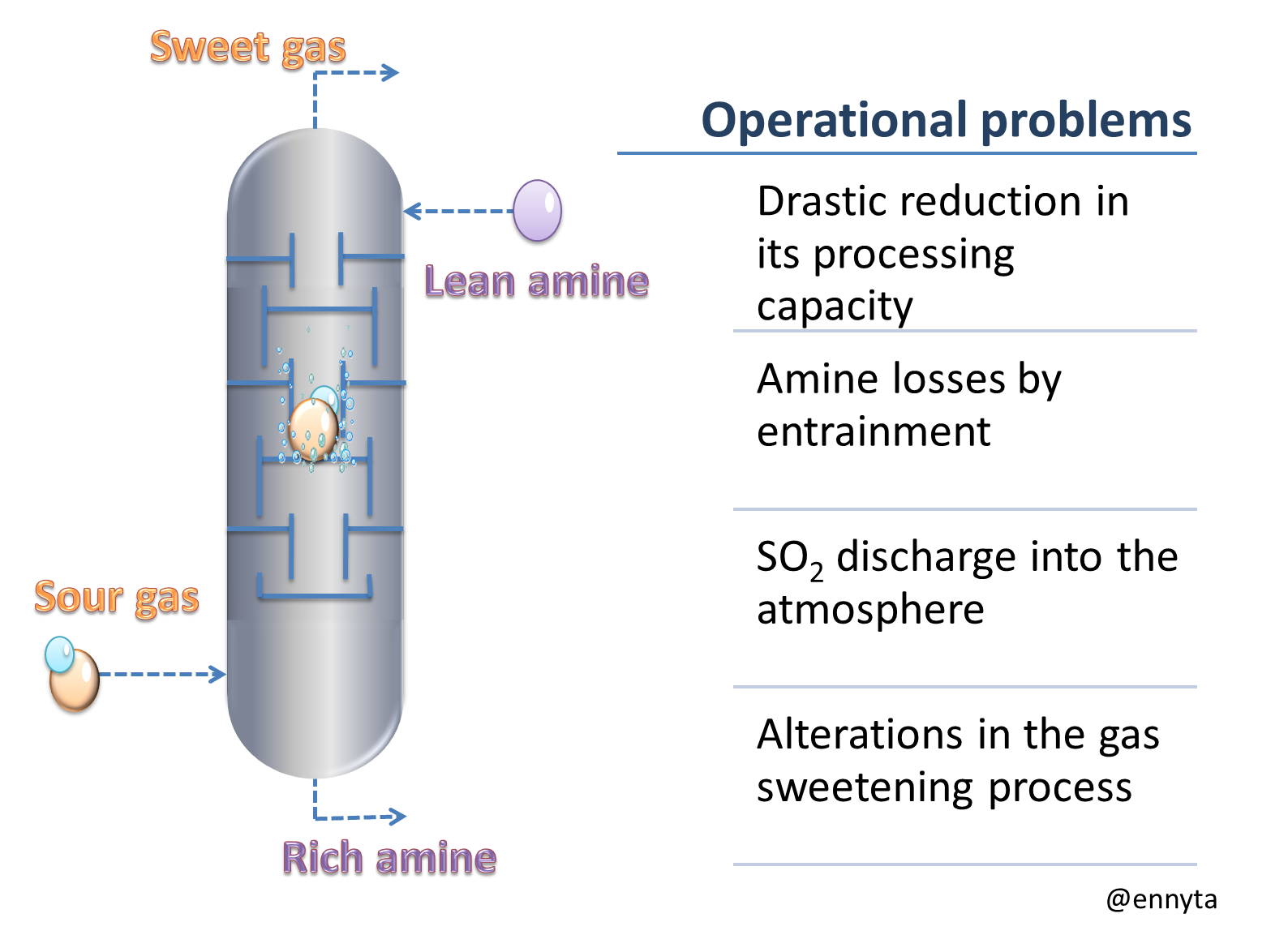

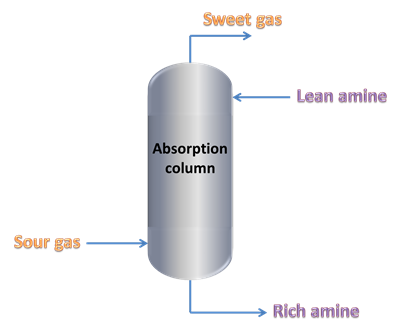

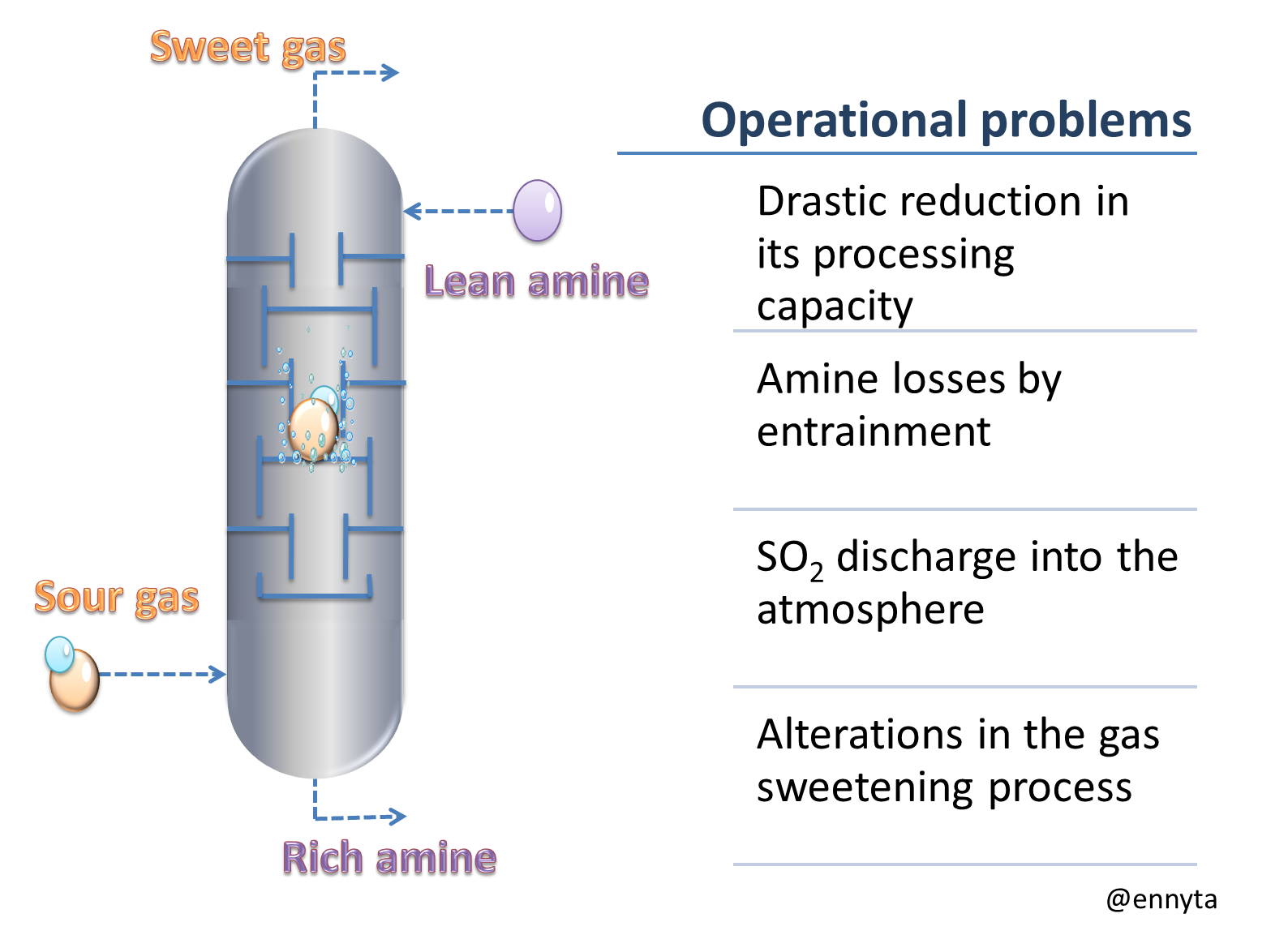

The sour gas components are absorbed into the amine via a chemical absorption method. The reason for this guideline is to prevent the condensation of hydrocarbons in the contactor and avoid the. An expert is invited to spend time in the IDM teaching techniques on particular pieces of equipment already situated within the IDM.

2018 Taiwan Expo in Malaysia. The reactions taking place during the absorption were examd. Smart Asia 2018- Booth D05.

2017 Myanmar Auto. Single or double column for increased product purity. WALAS S Chemical Process Equipment Selection and Design PDF WALAS S Chemical Process Equipment Selection and Design Jacqueline Alvarez Tostado Olguin - Academiaedu Academiaedu no longer supports Internet Explorer.

In amine gas treating the sour gas is fed to the bottom an absorber where amine solution is fed to the top along with any necessary make up water. For example Chemical Vapour Deposition CVD coating process technical data are included for the application of silicides to Carbon-carbon Ceramic and Metal. The overhead gases including CO 2 enter a CO 2-specific absorber column using the hot potassium carbonate process HPCP.

The plant treats 15 MMscfd of 450600 psig natural gas containing 30 grains mercaptan100 scf. Several parallel and consecutive reactions were found to take place during the absorption. Refluxed or non-refluxed columns to.

Amine Equipment Sulfur Recovery Engineering Inc

Absorber Tower An Overview Sciencedirect Topics

Amine Treating Unit Enggcyclopedia

Modification Of The Trays Valves Evaluation Of The Operational Conditions Of A Absorption Column Hive

Design Of A Water Wash Column In The Co2 Capture Process Using A Polyamine Based Water Lean Solvent Sciencedirect

Modification Of The Trays Valves Evaluation Of The Operational Conditions Of A Absorption Column Steemit

Flue Gas Purification System Is Regularly The Main Fuel Accessible To Work Power Generators And Compressor Stations In Remote Areas And On Seaward Stages Much

0 Response to "Amine Absorber Column Design"

Post a Comment